At Outokumpu, we believe that the future of stainless steel – and the metals industry at large – must be sustainable, innovative, and resilient. That belief is at the core of our new strategy: EVOLVE.

We have a long history of innovation at Outokumpu. Our site in Avesta, Sweden, was the first in the world to produce Duplex stainless steel. We invented the flash smelting process in the 1940s which transformed the global copper industry and remains one of the most important metallurgical innovations of the 20th century.

Now, after four years of research, we’re proud to announce our latest development. We’ve unlocked the paradigm between ore and metal and are positioned to lead the transition to green metals and show the path to a more decarbonized future.

The proprietary technology: reducing emissions while unlocking metal quality

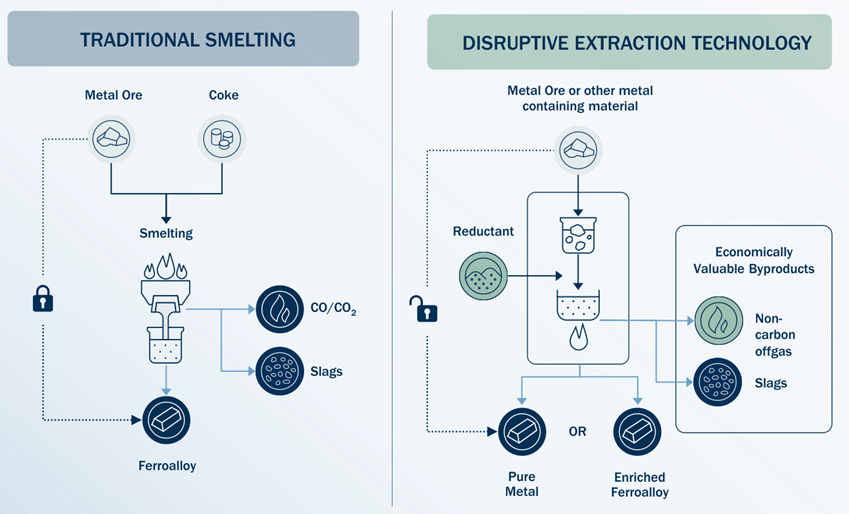

For over a century, metal production has relied on carbon-intensive processes. Traditional smelting, which uses coke as a reductant, is not only energy-hungry but also a major source of CO₂ emissions. At Outokumpu, we asked a bold question: What if we could break that link between metal production and carbon emissions?

The answer is the proprietary low-CO₂ metal extraction technology – a platform that represents a true paradigm shift in metallurgy.

This process eliminates the need for carbon-based reductants, replacing them with a more flexible method that produces non-carbon off-gases and significantly reduces environmental impact.

With this shift will come new sidestream opportunities, which will further drive cost-competitiveness and lower climate impact.

This new process, which is adaptable to a wide range of metals, will also unlock the strict linkage of the metal ore quality to the quality of the final product.

In other words, we will be able to create valuable products from resources that were previously considered marginal, uneconomic, or low-quality.

Currently, from the Kemi mine in Northern Finland, we are producing Ferrochrome that contains 53% Chromium. With the technology, we’re able to enrich this to a higher level – from 65%, all the way up to pure Chrome metal.

By producing higher-purity, higher-value materials from secure resources, we can more easily meet the challenging demands of tomorrow’s industries – from aerospace and defense to energy and advanced manufacturing.

From Lab to Industry: A Journey of Innovation

The journey of this groundbreaking technology began in 2021, with the launch of a dedicated research initiative to develop a carbon-neutral ferrochrome production process. In 2024, we established a state-of-the-art laboratory near Boston, US, where our team of world-leading scientists and engineers have worked tirelessly to turn vision into reality.

We’ve built a robust intellectual property portfolio that will secure our leadership in advanced metallurgy. And now, we’re entering the next phase: Our scale-up pilot phase in which we will further scale up the technology to 1 ton of metal per day and which will enable us to design the most economic and sustainable industrial setup for our next envisioned step – the industrialization.

In just a few years, we’ve scaled production of key materials from lab-scale experiments of 1g to larger lab scale of 1kg. By 2027, we aim to build a pilot plant in New Hampshire, US, to validate that scalability from 1kg of material to a full ton per day. The target timeline for the industrial plant is 2029-2030, and we expect to unlock the full commercial potential of the technology from 2030 onwards.

A Strategic Fit with EVOLVE

This technological transformation is not a side project – it is central to our future growth.

We’ll soon be able to create high-performing materials for high-value markets, with a clear competitive edge. Chromium materials gain value as they reach the highest levels of purity.

In the long run, this technology enhances our resilience. Our process offers a secure, sustainable, integrated supply chain for chromium – something which is missing in the Western world. In creating this supply chain, we are reducing geopolitical risk and strengthening our market position.

This breakthrough metal extraction technology will enable Outokumpu to look beyond the current limitations of metal availability. Utilizing the new process, Outokumpu is aiming to offer low-carbon-containing metals that are essential to produce stainless steel and advanced materials.

In a fast-changing world that is challenged by constantly growing geopolitical and environmental risks, access to cost-competitive, secure, and clean raw materials will be more important than ever before. Outokumpu has the most advanced platform to provide such offerings that are required beyond the important access to scrap metal.

And we achieve all of this while simultaneously lowering our climate impact. I strongly see that with limited Western supply and growing demand, there is a significant market opportunity for sustainable, high-performance materials – where only the sky is the limit.