Supply Chain News

December 3, 2024 Blog: Ensuring supplier sustainability is central to Outokumpu

November 7, 2023 Outokumpu and CRONIMET expand their partnership to take circularity to new heights – securing access to high-quality scrap near Outokumpu’s sites in Europe

October 6, 2023 Outokumpu signs a letter of intent with Greenland Resources Inc. to strengthen the future supply chain of low-emission high-quality molybdenum

May 30, 2023 Outokumpu seeks to strengthen the supply chain of sustainable nickel, acquires a share in FPX Nickel

Nov 1, 2022 Outokumpu visited suppliers in Colombia

May 4, 2022 Assessment on the allegations toward our supplier in Guatemala has been completed – purchasing remains suspended

March 6, 2022 Outokumpu acts firmly on allegations in Guatemala, placing new orders from Guatemala stopped

Jan 31, 2022 Site visit to Onca Puma site in Brazil conducted

Oct 29, 2021 Outokumpu launches sustainable sourcing initiative in raw material procurement

Mar 25, 2021 Outokumpu to develop its supplier monitoring and transparency in sourcing

Feb 23, 2021 Press release: Outokumpu expects its suppliers to act responsibly

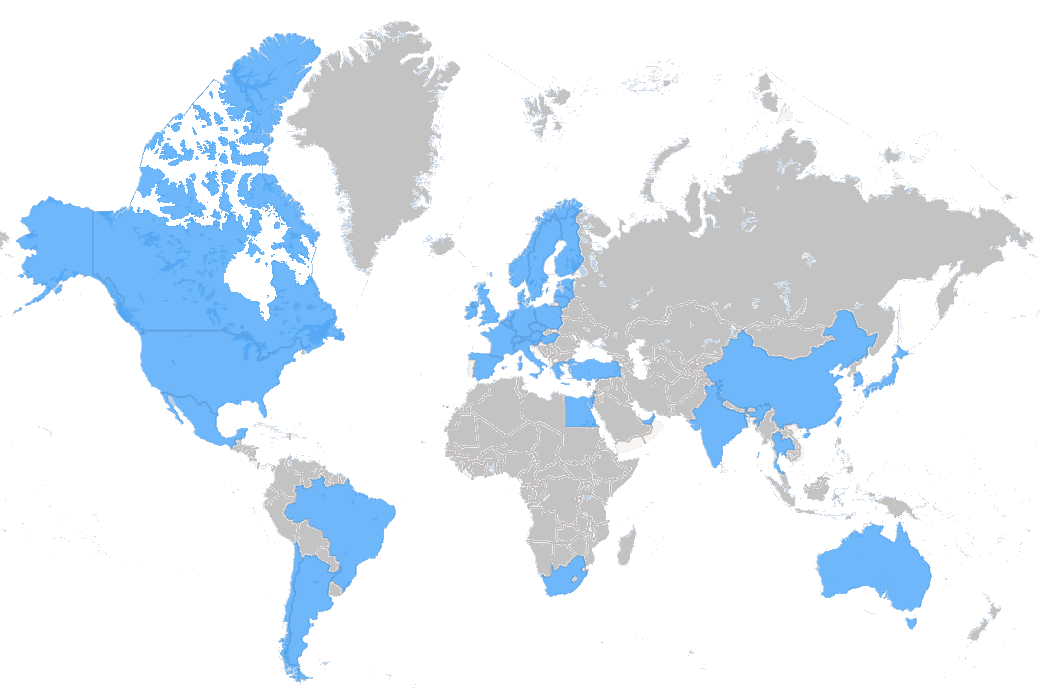

Global operations, local suppliers

Our procurement activities are divided into general procurement and procurement of raw materials. Raw materials are all ingredients that are in the steel we produce. General procurement purchases everything that is needed for our production activities and everything else we do at Outokumpu.

In 2024, we had

- Over 7,400 suppliers globally, local suppliers account for about 64% of purchases

- Direct suppliers in 58 countries

Expectations towards suppliers

As our customers require a lot from us as a supplier, we place the most stringent requirements on ourselves and require the same from our suppliers. We take into account the OECD Due Diligence Guidance for Responsible Supply Chain, and are implementing the UN Guiding Principles on Business and Human Rights in our operations and supply chain.

Outokumpu's suppliers have to comply with our Supplier Code of Conduct and Supplier Requirements.

For some products and raw materials, there are specific requirements. Conflict minerals are one example where supplies shall meet the requirements of the OECD Due Diligence Guidance, the Regulation (EU) 2017/821 of the European Parliament, and the U.S. Dodd-Frank Wall Street Reform and Consumer Protection Act. Suppliers of conflict minerals shall confirm to Outokumpu via the Conflict Minerals Reporting Template (CMRT) developed by the Responsible Minerals Initiative (RMI) the supply chain regarding mineral country of origin and that only approved smelters and refiners being utilized.

Supply Chain Due Diligence & Monitoring

Outokumpu applies a risk-based approach in supplier management. Upstream value chain mapping helps in setting the right priorities. Outokumpu buys all kinds of materials, products and services and some of them pose more sustainability risks and are more critical to Outokumpu’s operations than others.

A supplier shall be qualified before they can be approved and added to the Outokumpu supplier portfolio. In the qualification process, the potential risks and/or opportunities are identified and evaluated. This ensures that the suppliers comply with the Outokumpu’s requirements and can provide conforming raw materials, products, or services on a consistent basis.

Outokumpu monitors its suppliers through self-assessments, screenings and audits. Most of suppliers are also going through a monthly compliance screening for sanctions. Procurement uses mainly EcoVadis for self-assessments, which focus on environment, labor & human rights, ethics, and sustainable procurement. As a result of the self-assessments, improvement opportunities and requirements can be identified and agreed with the suppliers.

The countries in which our suppliers operate are mapped against country-based risk indices by TDi Sustainability’s Alert Index for Responsible Sourcing (AIRS), against the countries listed in the Dodd Frank Act Section 1502, as well as conflict-affected and high-risk areas (CAHRAs) as published by the European Union.

In addition to EcoVadis and the country-risk, raw material suppliers are assessed also based on e.g. available certifications and previous audit results. Based on these indicators, suppliers are selected for on-site reviews. Those reviews vary from sustainability visit, to sustainability audit to human rights impact assessment depending on the perceived risk. The below diagram describes the process in more detail. If you would like to know more about the conducted on-site reviews, please go to Site visits page.

As a result of our due diligence work, we have identified the salient impacts across our value chains. These impacts together with those that we have identified as salient in our own operations, are outlined on the Impacts on human rights page. We address these impacts in our Supplier Code of Conduct and Supplier Requirements to set the expectations towards our suppliers, and work together with them e.g. through sustainability audits and human rights impact assessments to prevent and mitigate the impacts. We also regularly evaluate the saliency of these impacts to monitor our progress and to account for any new risks.

Supply chain grievances

SpeakUp channel is an externally operated channel for Outokumpu employees and external stakeholders to report misconduct in our suppliers’ operations (as well as in Outokumpu’s own operations). This can be done confidentially and anonymously, if allowed by the local laws and regulations.

Sustainability contacts

For questions related to sustainable sourcing at Outokumpu: sustainable.sourcing@outokumpu.com

You can find the responsible contacts here