Max Menzel, Head of Sustainability & Technical Customer Service

There are many things that most people don’t know about stainless steel — for instance, how its non-corrosive property is based on the ability to “self-heal,” or that it is an extremely popular medium for artwork. Many people assume, for example, that stainless steel is commonly used in kitchen applications because of how it looks, when the reason is actually due to hygienic aspects and its thermo-conductive nature. But arguably, the most misguided perceptions of all revolve around stainless steel and the environment.

Steel production in all its forms is often thought of as dirty, wasteful, polluting, carbon-intensive, and unsustainable. To be fair, conventional production methods have been many of those things for much of steel’s history. Today, that no longer has to be the case. Key industry players are pioneering cutting-edge solutions for decarbonization and driving progress in the circular economy. Outokumpu is one of them.

But can a steel manufacturer really be a sustainability leader? Let’s take a look:

Recycling & circularity in the center of our business

The United Nations, World Economic Forum, European Union, and more are all in agreement: to ensure a healthy and equitable future for humanity, a fundamental shift toward circular economics is required. This has been the consensus for some time, yet when it comes to circularity, many businesses are still playing catch-up. Outokumpu, however, is leading the way.

From a global perspective, most stainless steel producers rely to a high extend on virgin materials as their primary ingredient, whereas European producers already rely mostly on recycled steel with Outokumpu leading the pack. All material streams associated with our production are carefully managed to prevent unnecessary waste, and we do our best to fully recycle and reuse as much byproduct as possible. Our stainless steel mill located in Tornio in Finland is, in fact, the largest material recycling center in Europe, and allows us to recycle thousands of tons of scrap annually. In practice, this means that the recycled material content of our stainless steel is more than 90% on average and reached an all-time high of 94% in 2022.

We also actively look for opportunities to partner with other companies and industries to accelerate circularity. The forestry sector, for example, produces a significant amount of renewable, bio-based wastes and residues. Some of these byproducts can be incorporated into the stainless steel manufacturing process (we’re referring to the use of bio-coke instead of conventional coking coal), eliminating the possibility of those byproducts being mismanaged, and reducing our own reliance on virgin raw materials. Another example is the consumer end, where we are also starting partnerships to accelerate circularity to ensure that we keep what’s good in the value chain.

If all stainless steel was made from Circle Green, it would cut the global carbon footprint by 250 million tons – every year

Outokumpu’s optimism and passion for circularity can be partly credited to the fact that stainless steel itself is a material that boasts not only great durability, but also is 100% recyclable. Used in a huge variety of applications thanks to its natural properties, stainless steel is a core material on which society is built – and can be used indefinitely. Products build from stainless steel can withstand up to 100 years of service. Whereas other materials (e.g. carbon steel) need to be replaced after 10-15 years. The challenge lies in making changes to production and supply processes so that not only the material itself is sustainable, but also the whole value chain it is a part of.

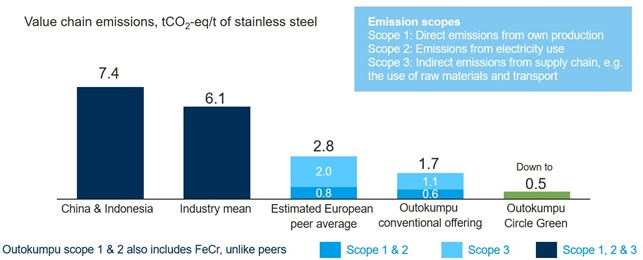

All of these things — recycling, increasing circularity but also managing the impact of supply chains — drive another crucial goal in sustainable development: reducing emissions. The more recycled materials we use, the less waste we create. And the better we steer our virgin material demand, the fewer CO2 emissions we generate. Likewise, strategically leveraging opportunities in supply and distribution allow us to minimize our carbon footprint across all scopes. In 2022, we were thrilled to launch a new product line, Circle Green, which has the smallest carbon intensity of any stainless steel product in the world, and up to a 92% lower footprint than the global average. Across all products, meanwhile, our carbon footprint is more than 70% lower than the global average.

What is required from a successful business today?

Recycling and circularity are what we often speak most about, as they are fundamental to our product and business model. However, our sustainability efforts writ large are much more encompassing. Sustainable Procurement, energy efficiency, water management, workplace health and safety, diversity, equity and inclusion, and continuous development of our people are among our priorities, and we integrate sustainability into all of our decision-making. We engage in initiatives and participate with organizations large and small, from the local to global level, to better understand and manage our impact on the world — because that’s what we believe is required to do business successfully today.

We strive to change many of the perceptions around manufacturing (namely, that it cannot be done sustainably), but we also want our sustainability story to transcend industries and regions. With that in mind, there are three lessons learned from our experience so far that we’d like to share far and wide, with organizations of every size and type:

1. Circularity is built on partnerships and collaboration

Circularity is not always an easy option. In many cases, it can be unlocked only through innovation, partnerships and for some organizations, even identifying opportunities for circular methods or processes may require extensive analysis. But with that said, circularity is still one of the most straightforward, obvious answers to strengthen sustainable value chains. To promote recycling and other forms of circularity is to maximize resource efficiency, limit environmental impacts, and often reduce emissions in the process.

Naturally circularity needs to cover the whole value chains to ensure products at the end of their lifecycle find their way back to the beginning. New ways of working, new partnerships and shared values are required to get full utilization of these benefits. While our experience tells us that no business can do much on its own to advance this goal, but through collaboration, Outokumpu is close to a truly circular economy already today.

2. You cannot do too much, but small steps supporting the way

The clock is ticking, and we have to speed up if we want to ensure a livable future on our planet. That’s why there is not a “too much” in sustainability. Outokumpu has pushed existing boundaries to the edge to offer a sustainable steel the market not expected to be reality. Circle Green is completely changing the potential to avoid CO2 when working with stainless steel. That’s a huge step, positioning the company as a forerunner and undisputed thought leader in sustainable stainless steel. At the same time this is only possible as we are taking small steps in the background to become more sustainable in all our processes for decades. It does not matter with what you start, but time to start shifting your business into a sustainable future is now.

3. Focusing only on recycling is not the solution

With all the focus on circularity and recycling we should not forget the burden of decarbonizing what we cannot recycle. Achieving a 100 % recycling rate for stainless steel is not a feasible target as we still see an increasing demand. That’s why Outokumpu is also focusing on primary material sources e.g., Nickel and Chrome – as essential ingredients of stainless steel – to reduce their emissions. On the one hand that requires assessment and management of our supplier base and on the other hand decarbonizing our own ferrochrome operations.

Pushing existing boundaries to the edge to offer a sustainable steel the market: Outokumpu Circle Green is completely changing the potential to avoid CO2 when working with stainless steel.

---

Can a steel manufacturer also be a sustainability leader? We don’t believe it’s possible — we know it. Together with our partners, we hope to be just the point of the spear, leading sustainable transformation for the entire industry, and beyond.

This article is part of Outokumpu's circular economy content program where we dig deeper into the themes such as decarbonization, recycling and innovations. Join us at acceleratecircularity.com