The hook and loop fastener is a ubiquitous phenomenon – used in just about everything from clothing and shoes to bandages and wiring sleeves in cars.

In the past, however, the use of hook and loop fastener has been limited by the material from which it is made. In case of plastic – the most common choice – usage in hot environments is a problem as well as situations where it might come into contact with chemicals. For this reason, hook and loop closures could not have been used in the engine compartment of vehicles.

Again and again

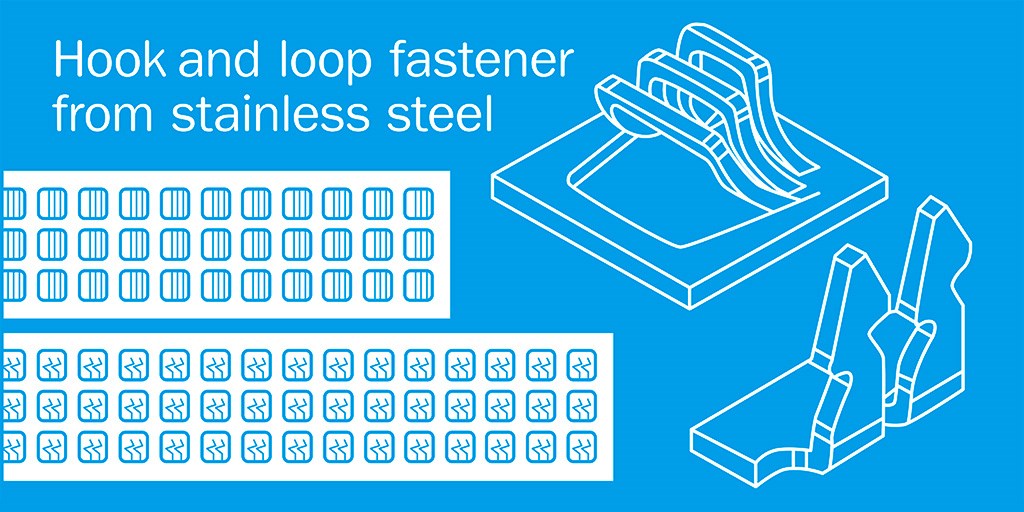

The game changer in this field was the innovative new fastener made of stainless steel, developed in Germany in 2008. Known as Metaklett, this was the first hook and loop fastener made of metal. The product offers all the advantages of a Velcro system combined with the strength of stainless steel.

The challenge here was to find a material which was strong, but at the same time flexible enough to achieve the required hook consistency. Like the plastic variant, Metaklett consists of two strips, one with loops and one with hooks. When they are pressed together, the hooks and loops engage. The closure is opened by pulling the strips apart resulting in the hooks being released from the pile. After they are disengaged from the loops, the hooks must return to their original shape to ensure that the closure can be used many hundreds of times – without loss of performance.

Grade for secure fastening

Outokumpu Core 301/4310 was the stainless steel selected for Metaklett. This Outokumpu stainless grade met the product manufacturing specifications: the stainless steel in question has superior tolerance of hot environments, up to 600° Celsius, is resistant to chemicals and extremely strong as it is able to hold 35 tons per square meter.

Against this background, it is no wonder that Outokumpu Core is a big favorite among the automotive industry – and with Metaklett, new uses are sure to emerge. Already, Metaklett is used in various applications requiring a secure fastening, which can be opened easily at will, such as for attaching ventilation and cable ducts in buildings or heat shields in the auto industry.