Additive manufacturing companies can extend their capabilities into stainless steel thanks to a new portfolio of powders. Andoni Sanchez-Valverde Erice, Sales/R&D engineer at Outokumpu Metal Powder, explains how spherical stainless steel powder feedstock can offer high-quality, customizable and sustainable solutions.

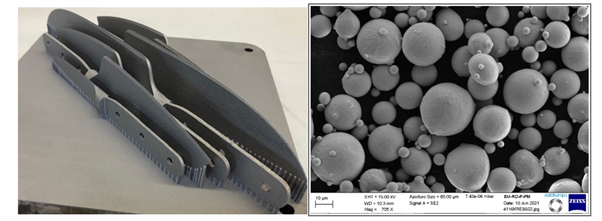

Additive manufacturing (AM), known sometimes as 3D printing, builds a solid component from a digital model by adding material layer by layer – see Figure 1. This contrasts with more traditional subtractive manufacturing that creates a product by cutting material away from a solid workpiece.

Figure 1 – knives produced by 3D printing (left) using metal power (right) – Knives photograph courtesy of Ernst Krebs KG

Designers are increasingly turning to AM thanks to its capability to create lightweight, complex and custom-made components in small quantities within very short lead times. However, until now, an important challenge has been the lack of suitable powders in stainless steel grades.

Outokumpu has responded to this gap by launching a new business to support AM. This has included the commissioning of an atomization plant at our mill in Krefeld, Germany. Our metal powder business offers a number of advantages for AM customers, including:

- As a global leader in stainless steel we bring Outokumpu’s extensive knowledge to the powder industry

- Our wide portfolio of metal powders comes in different grades, sizes and properties to suit a diverse range of applications. In addition to stainless steel it also includes nickel alloys

- Building on Outokumpu’s strong focus on sustainability, the powder plant is effectively a large recycling unit that uses scrap resulting from existing production processes.

- Our aim is to go beyond producing metal powder to create an AM ecosystem to support customers in the selection, design and manufacture of printed components.

AM covers a range of processes

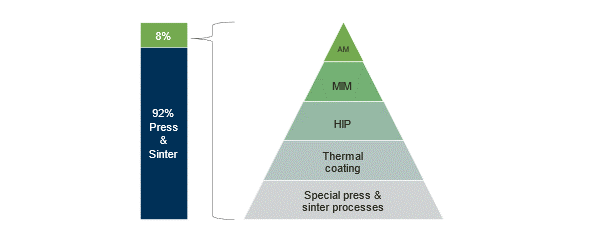

Spherical metal powder is the raw material that is used to produce parts in different Powder Metallurgy (PM) technologies. The most well-known process is Press & Sinter (see Figure 2), which has been used for around a century now. In recent decades this has evolved to include Hot Isostatic Pressing (HIP) and Metal Injection Molding (MIM).

AM technologies are now becoming increasingly important due to their capabilities to increase the complexity of produced parts, decrease lead times, avoid supply chain disruptions and reduce the weight of the parts to be produced. These advantages make metal powder and AM technologies a perfect match for high demanding applications in industries such as: aerospace, healthcare, oil & gas and automotive. That is why the expected Compound Annual Growth (CAGR) for AM technologies is expected to be between just over 26% until 2027. Source: AMPOWER report 2023.

Figure 2: The share of different powder metallurgy technologies in the global market

AM technologies include:

- Binder jetting technology

In binder jetting an adhesive binding agent is deposited on thin layers of powder. A 3D print head moves over the platform where it deposits droplets in the same way that a 2D printer puts ink on the paper. As each layer is completed, the powder bed moves downwards. The printer then spreads a new layer of powder onto the platform. This continues layer by layer until the component is complete. Following the printing the component is in a “green” unfinished state. It requires post-processing before it can be used. - Powder bed fusion

In powder bed fusion (PBF) a laser (PBF-LB) or electron beam (PBF-EB) is used to melt and fuse the metal powder together. As the process continues the powder is spread over previous fused layers by a blade or roller, gradually building up the component. - Direct energy deposition

In direct energy deposition (DED) a 3D object is formed by melting material as it is being deposited, using focused thermal energy such as a laser, electron beam or plasma arc. A gantry system or robotic arm is used to manipulate both the material feed nozzle and the energy source.

Stainless steel offers enhanced performance

The reasons for selecting stainless steel for AM are its superior corrosion and mechanical properties compared with other steel types, meaning that the component will last longer. The stainless steel powder also offers a more sustainable solution.

Currently, stainless steel is the third most-preferred feedstock for AM industries behind titanium alloys and nickel alloys. However, it is expected that by the end of 2027 stainless steel will be the most used feedstock with a market share of 33%. Source: AMPOWER report 2023.

How is stainless steel powder manufactured?

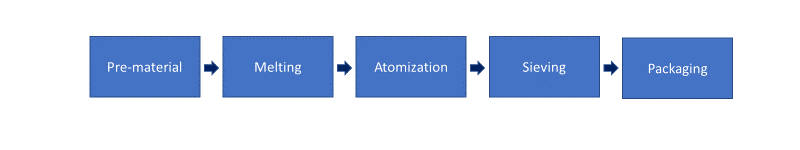

Outokumpu has invested in vacuum induction/inert gas atomization (VIGA) process equipment to produce stainless steel powder. A schematic of this is shown in Figure 3. It produces highly spherical metal powders that are perfectly matched for AM, MIM and HIP in a range of diameters between 0-300 µm.

Figure 3 – Schematic of the VIGA process

Figure 3 – Schematic of the VIGA process

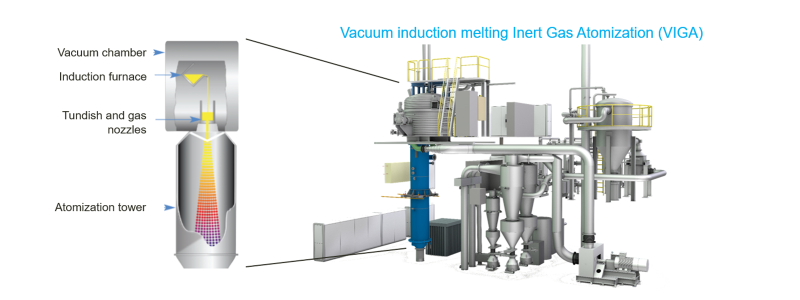

The details of the process equipment are shown in Figure 4.

Figure 4 – VIGA process equipment

Figure 4 – VIGA process equipment

- Pre-material: In most cases the pre-material is scrap from our flat product processing at Krefeld. This is a very strong sustainability argument behind the launch of Outokumpu’s metal powders business. The material is then cut into small pieces suitable for the process - typically 25 x 25 x 1~4 mm. These small pieces are then placed in the furnace crucible.

- Melting: This takes place under vacuum conditions to avoid possible oxygen contamination and burning of important elements of the melt. It is possible to measure and control all the important process parameters such as temperature, pressure and vacuum. The melt can also be chemically analyzed to check if further alloying is needed to achieve the correct composition. When the melt is ready the furnace is flushed with argon or nitrogen and the casting process begins.

- Atomization: The melt flows through the tundish and is atomized into very small droplets by nitrogen or argon gas at high pressure and temperatures (up to 32 bar and 450 C°). The small droplets solidify in spherical form and fly through the pipes to the cyclone. Here the solidified powder is separated from the gas and collected in the collection bins.

- Sieving: The powder is separated into different fractions by mechanical sieving and an air classifier to target different powder metallurgy technologies. As an example of what is possible, if a customer does not want to have more than 5% of their powder smaller than 20 µm then the air classifier can be used to separate the smaller powders from the batch.

Special features of Outokumpu’s powder business include:

- Possibility to use different sizes of crucible. This offers the flexibility to develop new alloys in small batches using a smaller crucible.

- Choice of either nitrogen or argon atomization gas depending on customer requirements for powder size and morphology

- Close-coupled atomization: special design of nozzles to increase the content of fine powders in the range up to 63 µm

- Fully equipped laboratory: All powder characterization techniques are included in our laboratories to provide customers with the highest powder quality. This includes both physical analysis (density measurement, flowability...) and chemical analysis.

Why is the choice of atomization gas important?

There are four main reasons why we offer customers the choice between nitrogen (N) and argon (Ar) as the gas to atomize their powders:

- Price: Nitrogen is less expensive than argon. This has an impact on the price of the finished powder. Powder atomized using argon will be more expensive.

- Morphology: Argon has a lower heat capacity than nitrogen. Therefore, powder atomized with argon has more time to achieve the desired spherical morphology before solidifying. Powders atomized using nitrogen solidify faster in a more irregular shape, although they are still highly spherical.

- Proportion of fine powders: When atomizing a batch under the same temperature and pressure conditions, the proportion of fine powders – which are of interest for some AM technologies - is higher when using nitrogen. The full explanation for this is quite technical. But the simple reason is that nitrogen atoms are smaller, so at the same temperature and pressure less energy is needed to divide the metal into a higher number of small droplets.

- Powder properties: The mechanical and corrosion properties of powders can be influenced by the atomizing gas. For example, nitrogen can increase both the machinability and corrosion properties of printed parts.

Anti-satellite system makes a crucial difference

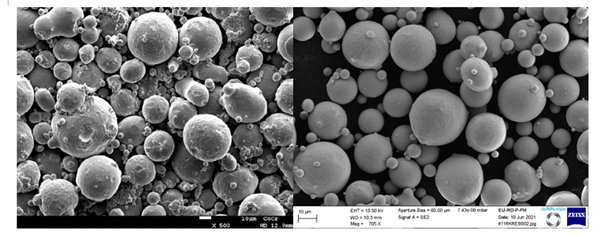

A crucial feature of Outokumpu’s powder production is the anti-satellite system. Satellites are small droplets that adhere to the larger spherical particles – see Figure 5. To avoid this, argon or nitrogen is recirculated into the atomization tower. This gas pushes the very small droplets to the bottom and the likelihood of satellites in the solidifying particles is reduced.

Figure 5 - a) spherical powder with a high amount of satellites b) Outokumpu’s spherical powder with a small amount of satellites

Figure 5 - a) spherical powder with a high amount of satellites b) Outokumpu’s spherical powder with a small amount of satellites

The presence of satellites rather than smooth, round powder will impact the quality of the printed parts in two ways:

- Spreadability: The spreadability of the powder is decreased if satellites and not perfectly spherical powders are used. This is important for the part of the process where the next layer of powder is spread onto the existing powder layer by the re-coater.

- Morphology: Satellites reduce the apparent density and the packing of the powder. If the density of the powder is decreased there is a higher risk of failure in the printing process, due to pores or air gaps between the particles.

Producing a range of powder sizes

Each powder metallurgy technology requires different powder sizes. That is why Outokumpu’s products are differentiated not only by the stainless steel or nickel grade, the gas used for atomization and also the size. Our atomizer can produce powders up to 300 µm to suit these AM and PM technologies:

- Binder jetting technology (BJT): <20 µm

- Laser powder bed fusion (PBF-LB): 15 to 45 µm and 20 to 63 µm

- Electron beam powder bed fusion (PBF-EB): 20 to 150 µm

- Direct energy deposition (DED): 20~45 to 150 µm

- Metal injection molding (MIM): <20 µm

- Hot isostatic pressing (HIP): 0-300 µm

Extending the portfolio of stainless steel grades

Currently, the stainless steel grades used most widely in AM and other powder technologies are 316L and 17-4PH. Outokumpu’s strategy is to introduce new stainless steel grades to this sector that are a closer match for the demanding requirements of high-performance applications.

The “commodity” stainless steels grades developed for powder metallurgy technologies are:

- Supra 316L (1.4404):

A low-carbon alternative to 316. This minimizes carbide precipitation as a result of heat input, for example during welding, giving improved resistance against intergranular corrosion. 316L/4404 is suitable for a wide variety of applications in the automotive, chemical, petrochemical and medical industries. Typical products include flanges, valves, and medical devices. - Dura 17-4PH (1.4548):

A well-known martensitic precipitation hardening (PH) steel with alloying elements such as chromium or nickel. It has good corrosion properties and excellent mechanical properties up to 300°C. It is used in the aerospace, pulp and paper and nuclear industries for products such as mechanical seals, pumps or turbine blades.

Added-value special stainless steels grades developed for powder metallurgy technologies include:

- Ultra 904L (1.4539):

Special grade for high-corrosion environments. It is a high-nickel and molybdenum austenitic stainless steel with very high corrosion resistance. It was originally developed for handling sulfuric acid at ambient temperatures and is now used in a broad range of applications in the oil and gas and chemical industries. Typical parts produced from 904L are pumps, valves and flanges. - Therma 253MA (1.4835):

Special grade for high-temperature applications. This is an austenitic stainless steel with excellent oxidation and creep resistance in cyclic conditions that is best employed in temperatures up to 1150°C. It is used in the oil and gas, aerospace and motorsport industries for parts such as fittings and heat exchangers. - Dura 4116 (1.4116):

Special grade that is a high-hardness martensitic stainless steel with improved corrosion and wear resistance compared to other martensitic stainless steels. It is used in the healthcare and consumer goods industries for products such as medical devices and knives. - Nickel-free austenitic stainless steel powder (modified 1.4678):

This specially-developed Ni-free stainless steel powder is an ideal substitute for 316L or Co-Cr alloys. It is also a perfect grade to avoid Ni-allergic reactions in health applications or consumer good applications for products such as watches and other items worn close to the body.

Outokumpu’s portfolio of metal powders also features Ni- based alloys:

- Alloy 625:

For use in very harsh, corrosive environments at high temperatures. Alloy 625 combines nickel, chromium, molybdenum and niobium that give excellent corrosion properties and excellent mechanical properties. When compared with Alloy 718, Alloy 625 has a greater overall resistance to oxidation. It is used in the oil and gas, aerospace and defense industries for components such as fittings, rocket parts, heat exchangers and vessels. - Alloy 718:

This Ni-based alloy is also used for high corrosion environments and at high temperatures. It has additions of molybdenum, tantalum, aluminum and titanium that provide higher strength and better weldability, as well as improved stress corrosion cracking (SCC) resistance than alloy 625. It is used in the oil and gas, aerospace and defense industries for components such as fittings, rocket parts, heat exchangers and vessels.

Building a stainless steel AM ecosystem

Our aim with this new development at Krefeld is to build a stainless steel AM ecosystem that will open up new possibilities for manufacturers operating in the world of additive manufacturing and powder metallurgy. We anticipate that two main groups of customers will benefit most from joining Outokumpu in this venture:

- Companies that already know Outokumpu through our stainless steel products but have not used AM previously

- Customers that are already experienced in AM and now want to take it to the next level by using higher-alloyed stainless steel grades and/or to benefit from our leadership in sustainability.

Want to know more about our metal powder portfolio or have any specific questions for us?

Get in touch with us at: metalpowder@outokumpu.com