Technical standards are vital to the success and efficiency of industry. Thomas Kirchhartz, Outokumpu’s lead standardization manager based in Krefeld, Germany, is driving our standards program and says: “Engineers need standards and regulations to make products, to buy and sell them, and to design and operate systems with confidence. They look to technical standards as the first port of call for data on materials, performance, dimensioning, tolerances and other important information.

“Being included in a standard also shows that a product has reached maturity in terms of the supply chain and availability. Therefore, if a material is not listed in the standards, many engineers won’t even consider using it.

“Without standards, engineers would need to go back to first principles for even the simplest jobs. For example they would need to design and manufacture even the most basic fasteners like nuts and bolts from scratch and carry out extensive laboratory testing to check their capabilities.”

It is therefore fitting that the ISO 3506 standard for corrosion-resistant stainless steel fasteners is the first success in our current program to extend the coverage of duplex grades in existing standards. It is now providing engineers with data so that they can specify duplex fasteners along with sheet and plate materials.

The new revision has been expanded from four to seven sections and now includes fasteners made from four duplex grades using the same naming convention as the pre-existing system for austenitic, ferritic and martensitic grades.

Fastest-growing segment of stainless steel market

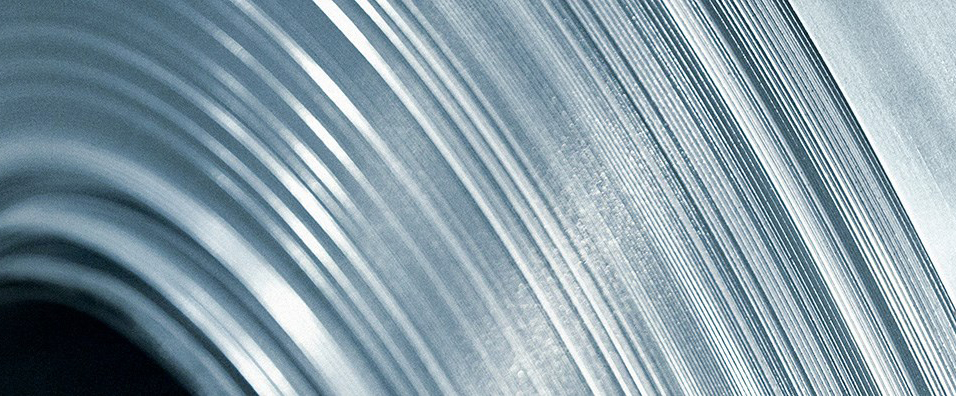

Duplex grades have been included in some technical standards since the 1980s, when they gained popularity in the pulp and paper, chemical processing and offshore oil and gas industries for their high strength and corrosion resistance.

Today, this combination of properties is attracting much wider interest due to its potential for sustainability. High strength and corrosion resistance can deliver long-lasting and lightweight structures that have a resilient surface that needs little or no maintenance.

As a result, the duplex family of grades is the fastest-growing segment of the stainless steel industry. Thomas says: “We’re currently seeing a lot of interest from architects and transport networks who want bridges that look good, provide a long life and don’t need regular closure for maintenance.

“Demand for duplex grades is also growing in the chemical, processing and food and beverage industries. The corrosion resistance is valuable as storage tanks and processing vessels don’t need protective coatings and the high mechanical strength means thinner tank walls. That saves costs across material purchase and fabrication, lifting and handling, and civil engineering.”

Next steps

Now that the new sections of ISO 3506 have been published, Thomas is focusing his attention on adding duplex grades to several other standards with the goal of presenting duplex grades as an option alongside other materials. As a committee chair, he is working closely with experts from a wide range of industries, as well Outokumpu’s own experts in R&D, sales and production.

He concludes: “It is essential that standards contain the right data and can be understood by both technical experts and new recruits, therefore we follow a rigorous process of discussion and approval over several years.

“It’s important not just to include duplex stainless steel in the standards that cover the products that we provide directly. To have confidence in the grades, engineers also need to see them covered in a wide range of standards. That’s why we’re now working to encourage the addition of duplex grades to standards that cover other aspects of design, production, operations and maintenance.”