Lockout/tagout

LOCKOUT/TAGOUT means securing a equipment from unforeseen movements or flows. To turn off the work switch or valves is the most obvious way, but remember to also…

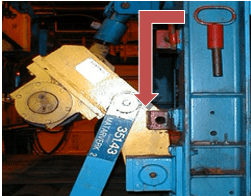

...use the mechanical blocks to prevent parts of the facility from moving because of, for example, weight or pressure drop

…empty, drain or in other ways prevent pressure/energy from being left in the system.

Lockout/Tagout applies for every normal case when work will be done on machines and work equipment, such as:

- All type of maintenance (preventive and corrective)

- Stripping of remaining material

- Cleaning, washing, remediation (for example, with high pressure spray)

- Construction work in or in direct connection to the machine

- Pressurized facility parts

Personal lock - Everyone that will be working in a facility must use personal locks, "One lock - one key"" that is clearly marked with name and telephone number, as well as with company name for contractors.

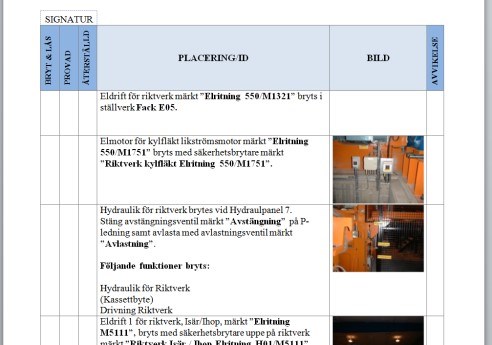

Lockout/Tagout instructions - In the planning of the work, an assessment is done on which Lockout/Tagout instructions shall be printed. Lockout/Tagout instructions are available for each part of the equipment.

- Use the checklist in the Lockout/Tagout instructions to identify all the break points.

- Do not blindly trust the instructions, but pay attention to whether there are additional positions that need to be secured!

- Sign when you have shutdown, locked and tested.

- Have you noticed what it says under "Special information"?

- Are there other risks that the instructions do not describe?

- Note any shortcomings. For example, moved/replaced work switches.

Blocking

Blocking lock can be used if a work is in progress over several work shifts. Certain work groups at Outokumpu Avesta Works have blocking locks, but not the contractors.

- Each work group has a set of blocking locks with a common key.

- When working, the facility is locked with a blocking lock and a personal lock.

- Printed Lockout/Tagout-instructions are used to find all break points.

- When shifts change, the personal lock is removed and the 2nd performer lock with their personal lock. (The same Lockout/Tagout-instructions are used)

- After completion of the work the 2nd performers remove their personal locks, as well as the blocking locks.

Blocking lock does not replace the personal lock.

Area lockout

- Area lockout can be applied if many people work in the same area.

- Two designated, suitable persons secure the equipment according to the Lockout/Tagout-instructions.

- Keys for the locks are put in a group lock box which is locked with personal locks.

- Completed checklist is placed next to the lock box.

- All persons working in the facility lock the lock box with their personal lock.

- After completion of the work, respective performer takes their personal lock and the equipment can be unlocked again.

Barriers

Openings and holes with risk of falls must be protected with a fall protection railing or be protected with covering. Guardrails shall surround the entire opening. If you choose to cover the hole with a disc or equivalent it shall be sustainable, be secured and shall be clearly marked. When there are lifts or other heavy vehicles that can run in the vicinity, the coverage or the protective railing shall be suitable for it.

When barriers are necessary for other types of risks, an assessment is made on a case by case basis on how stable the barrier needs to be. Barriers shall always display the reason for the cordoning off, contact person/contact information and how long the barrier shall be maintained.

Online safety course and knowledge test

To receive your certificate, read through the following sections and then take the knowledge test:

4. Coordination of contractors

6. Safe access